G-DRONES will aim at demonstrating the following impacts for the open pit mining industry:

- Increase production efficiency: Perform single area inspection in less than 20 min after blasting, reduce waiting times by 30-40 mins. Currently the waiting time after blasting is 60-90 mins.

- Increase cost efficiency: Create more 250 000 SEK/hour of savings from immediate after blasting inspection and reducing the waiting times before continuing the loading.

- Create a safe work space: Zero exposure to poisonous gases to human workers

- Increase acceptance of the mining industry from the reduction of risks for workers and improve the overall working place attraction.

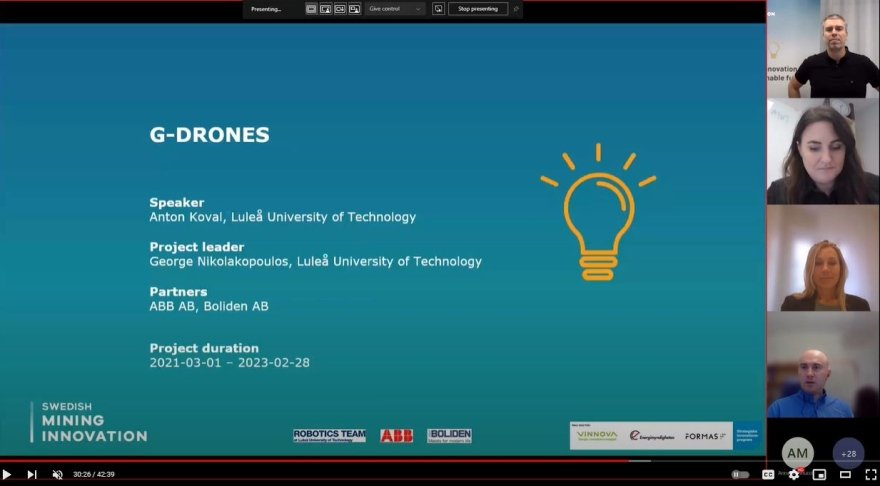

G-DRONES has been funded from SIP-STRIM and VINNOVA.